How aluminum casting contributes to sustainable manufacturing

Wiki Article

Just How Aluminum Foundries Add To Various Industries: A Thorough Summary

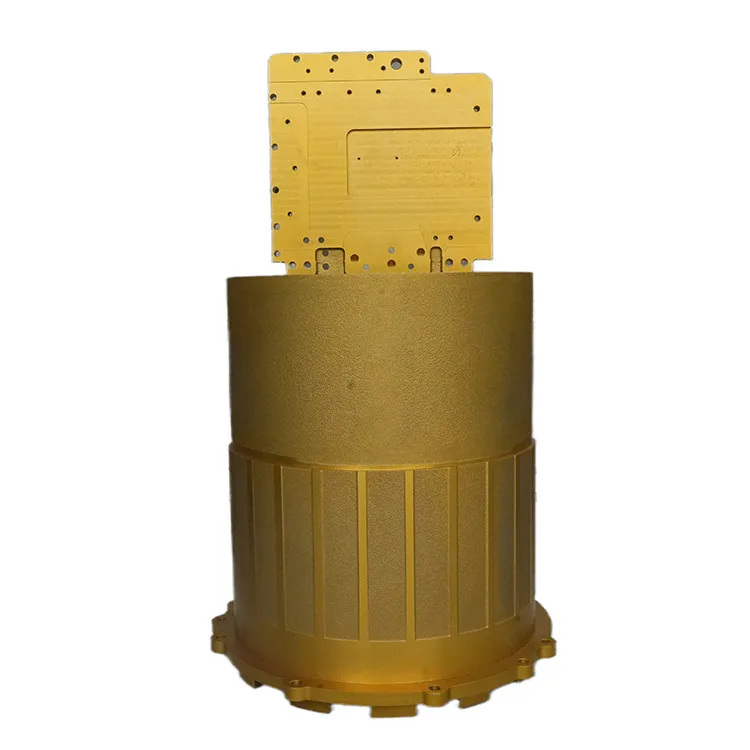

Aluminum foundries work as important suppliers throughout multiple sectors, consisting of auto, aerospace, building, and electronic devices. They produce parts that are not only lightweight yet also long lasting, enhancing the efficiency of different items. With advanced casting strategies and a commitment to sustainability, these foundries are adjusting to fulfill evolving market demands. As they introduce, the effect of aluminum spreadings on various applications elevates important concerns about the future of manufacturing. What exists ahead for this crucial sector?The Role of Aluminum Foundries in the Automotive Industry

As the automobile market progressively accepts light-weight products to boost gas efficiency and performance, light weight aluminum shops play an essential role in this evolution. These centers specialize in the production of light weight aluminum castings, which are essential parts in contemporary automobiles. By giving high-strength, light-weight parts, aluminum foundries enable producers to decrease the overall weight of lorries, inevitably resulting in enhanced gas economic climate and lowered discharges.Aluminum's resistance to corrosion further improves lorry durability, making it an attractive option for car manufacturers. Foundries use innovative strategies such as die casting and sand casting to develop detailed and specific components, making certain that they satisfy strict sector requirements. In addition, the ability to reuse aluminum successfully contributes to a much more sustainable production process. As the automotive market proceeds to introduce, aluminum factories will continue to be essential in supplying the materials necessary for the future generation of vehicles, sustaining both performance and ecological goals.

Aerospace Applications of Aluminum Castings

Aluminum castings are important to the aerospace industry, supplying a combination of lightweight stamina and resilience that is critical for aircraft performance. These castings are utilized in different components, such as engine components, architectural structures, and touchdown equipment, where weight decrease is vital for fuel effectiveness and general safety and security. The versatility of aluminum permits complex geometries that boost wind resistant effectiveness while keeping architectural integrity.Innovations in casting modern technologies have actually boosted the accuracy and surface finish of light weight aluminum components, decreasing the need for substantial post-processing. This effectiveness not just accelerates production timelines yet additionally decreases prices, making light weight aluminum an appealing option for producers. The rust resistance of aluminum guarantees long life and integrity in harsh operating atmospheres, better establishing its duty in aerospace applications. As the market develops, light weight aluminum spreadings proceed to be an important material, driving development and supporting the growth of next-generation airplane.

Building Market Developments Via Light Weight Aluminum

The building market has increasingly taken on light weight aluminum due to its light-weight homes and versatility, paralleling its effective applications in aerospace. Advancements in aluminum layout have actually led to more powerful, more reliable structures, making it possible for building contractors and architects to explore brand-new possibilities. The material's resistance to corrosion and low upkeep needs make it especially appealing for both business and residential jobs.Light weight aluminum's adaptability helps with the development of intricate styles, enabling visual enhancements that were formerly tough with traditional materials. Prefabrication strategies have actually additionally developed, using light weight aluminum to lower construction time and prices considerably. In addition, the power efficiency of light weight aluminum systems-- such as window frames and roof covering-- adds to sustainable structure methods, straightening with modern environmental requirements. As the construction sector remains to welcome these developments, aluminum's role is anticipated to increase, driving more advancement and click resources adding to the growth of resistant infrastructures.

Electronic devices and the Need for Lightweight Light Weight Aluminum Components

With the fast improvement of technology, the demand for light-weight light weight aluminum parts in the electronic devices sector has surged. As devices come to be more portable and portable, producers look for products that provide both toughness and weight reduction. Light weight aluminum, with its exceptional strength-to-weight proportion, has actually arised as a recommended choice for parts such as casings, warm sinks, and architectural assistances.Using aluminum not only boosts item performance but additionally adds to power effectiveness, as lighter devices call for much less power during operation. Furthermore, light weight aluminum's superb conductivity makes it excellent for digital applications, making certain effective warm dissipation and reducing the threat of overheating.

As customer choices shift in the direction of smooth and lightweight gizmos, light weight aluminum shops play a necessary function in fulfilling the progressing demands of the electronic devices sector (Aluminum Casting Company). Their capacity to produce precise and top quality light weight aluminum parts supports technology, making it possible for makers to press the boundaries of layout and capability

Sustainable Practices in Aluminum Foundries

As the electronics market increasingly prioritizes sustainability, aluminum foundries are adapting their methods to align with these ecological objectives. Lots of shops are carrying out reusing programs that reclaim aluminum scrap, greatly minimizing the demand for basic materials and reducing waste. By making use of energy-efficient modern technologies, these facilities are reducing their carbon impact; as an example, using electric heating systems rather than conventional gas-fired ones can cause considerable power savings.Furthermore, aluminum shops are purchasing water conservation actions, such as closed-loop systems that recycle water used in cooling procedures. These practices not just reduced water intake but likewise alleviate the ecological impact connected with wastewater discharge. Moreover, lots of foundries are checking out renewable power sources, such as solar and wind power, to satisfy their energy needs sustainably. With these efforts, light weight aluminum foundries exhibit a commitment to environmental stewardship while remaining to satisfy the needs of the electronics industry.

Future Trends in Light Weight Aluminum Foundry Technologies

Arising technologies are positioned to transform light weight aluminum foundries, improving efficiency and product high quality while progressing sustainability efforts. Technologies such as man-made intelligence and artificial intelligence are expected to optimize production procedures by forecasting devices failings and boosting resource allowance. The integration of sophisticated robotics will certainly improve operations, minimizing labor prices and minimizing human error.Additive manufacturing, or 3D printing, is additionally obtaining traction, making it possible for the a fantastic read manufacturing of intricate geometries that were previously unattainable with traditional approaches. This change can bring about considerable product financial savings and minimized waste. In addition, smart foundries utilizing IoT (Web of Things) innovations will enable real-time surveillance and information analysis, fostering proactive decision-making.

The fostering of cleaner melting innovations and recycling strategies will additionally decrease the ecological footprint of aluminum factories, making them much more lasting. Jointly, these fads signify a future where aluminum foundries can run with greater efficiency and duty.

Frequently Asked Inquiries

What Are the Ecological Effects of Light Weight Aluminum Foundries?

How Do Foundries Make Sure High Quality Control in Light Weight Aluminum Spreading?

Factories ensure top quality control in light weight aluminum spreading by applying strenuous inspection processes, utilizing advanced technology, conducting routine material screening, and sticking to industry requirements, thus preserving consistency and integrity in their finished products. aluminum casting.What Is the Ordinary Lifespan of Aluminum Cast Components?

The typical lifespan of light weight aluminum cast components generally ranges from 10 to half a century, depending on factors such as environmental conditions, usage, and upkeep. Proper care can substantially enhance their toughness and performance over time.Exactly How Are Aluminum Alloys Selected for Certain Applications?

Aluminum alloys are picked based on elements such as toughness, corrosion resistance, weight, and thermal conductivity. Designers assess the particular needs of applications to figure out one of the most suitable alloy for finest performance and resilience.What Are the Safety And Security Regulations for Aluminum Factory Workers?

Security regulations for light weight aluminum foundry workers include personal safety devices requireds, air flow requirements, direct exposure restrictions to unsafe materials, and protocols for taking care of molten metal. Conformity assurances worker safety and security and minimizes health and wellness threats connected with shop procedures.As the automotive sector progressively accepts light-weight materials to boost fuel efficiency and performance, website link light weight aluminum shops play a crucial role in this development. As customer preferences change towards sleek and lightweight gadgets, aluminum shops play a crucial duty in satisfying the progressing demands of the electronics industry. As the electronics industry significantly prioritizes sustainability, aluminum foundries are adapting their practices to align with these ecological objectives. Several factories are executing reusing programs that reclaim aluminum scrap, considerably decreasing the demand for raw products and lessening waste. Safety policies for aluminum factory employees consist of personal protective tools requireds, ventilation needs, direct exposure limitations to unsafe materials, and procedures for dealing with molten metal.

Report this wiki page